Wardsweb

Well-known member

As not to hijack the other thread, I'll post some more on my 2-channel rig's speakers here.

This all started around Jan 2006. My DIY Brazilian rosewood JBL corner horns were nice but just didn't have the high end sparkle that I wanted. This after my custom Altec A7 Voice of the Theatre didn't were not that great at near field. Imagine that a speaker with a 15 foot bass fold not working well in my living room. So on to a new design.

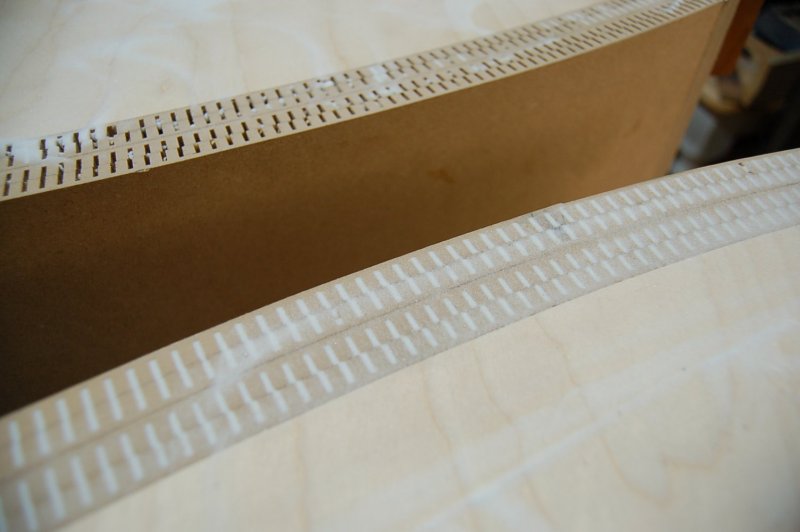

Baltic birch and MDF with CNC bracing and kerf MDF sides.

This all started around Jan 2006. My DIY Brazilian rosewood JBL corner horns were nice but just didn't have the high end sparkle that I wanted. This after my custom Altec A7 Voice of the Theatre didn't were not that great at near field. Imagine that a speaker with a 15 foot bass fold not working well in my living room. So on to a new design.

Baltic birch and MDF with CNC bracing and kerf MDF sides.